Monday

BMW Edge

A 290-to-450 seat indoor amphitheatre situated at the river end of the Atrium, the BMW Edge has been designed for music, small to medium scale theatre, comedy, talks and presentations, launches and cabaret.

The Melbourne Cricket Ground, Alexandra Gardens, the Victorian Arts Centre spire and the Yarra River are all in view through the crystalline lining of the venue. The fit out of this new cultural venue was made possible through the generous support of BMW Group Australia.

http://www.federationsquare.com.au/index.cfm?pageID=29

LAB ARCHITECTURE STUDIO

The Atrium

The Atrium is a unique covered public space, providing a complement to the open square. Offset into two distinct elements, by the intersection of the "Crossbar", the Atrium is a galleria-like structure. As a continuously open, publicly accessible space, the Atrium effectively and dramatically connects the city, through Federation Square to the Yarra River.

The northern part of the Atrium, as a glazed covered street, provides a forecourt to the Ian Potter Centre through an open interior volume 16 metres high and up to 18 metres across. The southern end of the Atrium steps from the deck level over the railway down to the river. Within this transition, an indoor amphitheatre, the BMW Edge, provides a public theatre for incidental daily events, casual entertainment or ticketed musical, comedy and other performances. The design is tuned acoustically to provide a space suitable for small to medium sized music and theatre ensembles, including chamber orchestras.

The open galvanised structural frames of the Atrium evolved from the same triangular geometry as that of the facades , but developed as a folded three-dimensional system glazed both inside and out. The deep space of this supporting frame acts as a thermal chimney, evacuating the build-up of hot air.

http://www.federationsquare.com.au/index.cfm?pageID=29

This technique produces significant challenges for builders, not only in the prefabrication of the steel part but also issues of health and safety: gantries, roof walkways and roof edges must be built to ensure safe working conditions and enable continuous construction.Designing the ends and sides of these buildings is a problem. Either the architect sweeps the building over and into the ground, so it appears to bury itself, or it is severed and covered with sheet glass arranged like shrouds. Spencer Street has been designed that way, with the Spencer and Collins streets walls open and engaging the streets. The characteristic is opposite to the previous station, which was arranged behind a private wall.

This technique produces significant challenges for builders, not only in the prefabrication of the steel part but also issues of health and safety: gantries, roof walkways and roof edges must be built to ensure safe working conditions and enable continuous construction.Designing the ends and sides of these buildings is a problem. Either the architect sweeps the building over and into the ground, so it appears to bury itself, or it is severed and covered with sheet glass arranged like shrouds. Spencer Street has been designed that way, with the Spencer and Collins streets walls open and engaging the streets. The characteristic is opposite to the previous station, which was arranged behind a private wall.

Sometimes the product is called warped architecture, which is characterised by the forms that appear to morph and warp like an organic body - rather than the more traditional translation of architectural space and form.Architecture and engineering have difficulties with the construction of irregular forms; they do not easily fit the construction business, where steel is usually made straight, bolts are regular and welding done to true line.

Sometimes the product is called warped architecture, which is characterised by the forms that appear to morph and warp like an organic body - rather than the more traditional translation of architectural space and form.Architecture and engineering have difficulties with the construction of irregular forms; they do not easily fit the construction business, where steel is usually made straight, bolts are regular and welding done to true line.More, the covering of a curved surface brings its own problems; most steel claddings (roofs and walls) are straight and not easily shaped.Some materials can be folded, copper, zinc sheeting and plastics among them, and tiles can be laid to achieve curvature.At Spencer Street and at Federation Square, the roof sections have been segmented into generally triangular shapes, small enough so they can be fixed straight but each joint is a hinge, which allows the roof to curve. Over the steel skeleton a skin of triangular roofing is fixed as a series of small flat panels that, from a distance, and in concert with the rest of the roof, appears to curve.

Each design is different, yet appears to be part of a portfolio by one creative team. Each adapts the concept of column-free space, huge sculptured roofs and innovative engineering. The structure is simple enough - columns with huge Y tops that gather the steel trusses, and a thin roof fixed over the curved surface. Ends are filled in with glass walls.Grimshaw has sculpted steelwork over several curves, which produces the first serious difficulty for engineers and manufacturers. Curved structures are difficult to design by mathematical computation and even more complex for steelworkers and welders to produce.Although this architectural expression appears to be loose and free-form, it is a carefully translated exercise in computer-generated imagery, avant-garde in the use of technology and fulfilling a continuing pattern, especially among British architects, for high-tech solutions to design challenges. This style of design is sometimes called biomorphic, meaning an attempt to generate forms that seem to be natural, yet are produced using the most sophisticated image-production methods.

Each design is different, yet appears to be part of a portfolio by one creative team. Each adapts the concept of column-free space, huge sculptured roofs and innovative engineering. The structure is simple enough - columns with huge Y tops that gather the steel trusses, and a thin roof fixed over the curved surface. Ends are filled in with glass walls.Grimshaw has sculpted steelwork over several curves, which produces the first serious difficulty for engineers and manufacturers. Curved structures are difficult to design by mathematical computation and even more complex for steelworkers and welders to produce.Although this architectural expression appears to be loose and free-form, it is a carefully translated exercise in computer-generated imagery, avant-garde in the use of technology and fulfilling a continuing pattern, especially among British architects, for high-tech solutions to design challenges. This style of design is sometimes called biomorphic, meaning an attempt to generate forms that seem to be natural, yet are produced using the most sophisticated image-production methods.

Its Leuven station project (Belgium) is similar to Spencer Street, with large pipe-curved frames holding a rolling roof that has skylights. The same system for movement operates in most of these halls: open, no columns, the trains, baggage-handling trucks, and catering vehicles operating around platforms, and retail shops, offices and control rooms suspended into the huge space.

Even more sculptured is Grimshaw's design for Frankfurt's Messehalle, where the shiny, silver roof hovers like a school of fish over a column-free open space. The forms become symbolic, more than mere building, they take on other meanings.

Characteristic is the shapely, seemingly random roof form, not rectangular slabs of modernism, but a complex curve-on-curve, made understandable using computer-generated images, which are used also for structural analysis.

Other Grimshaw-designed terminuses are an investigation into the typology of modern open spaces; at Bilbao (Spain), Heathrow and Waterloo (London), Manchester and in Zurich.

Sunday

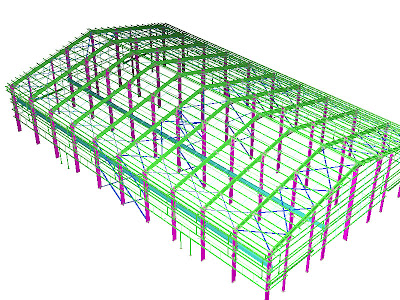

To explain it in its simplest form I ventured to the notorious Bunning’s warehouse to undertake a little more research in this construction methodology of the portal frame. Basically most portal frames are achievable through the use of steel as it has the properties of rigidity over a long distance. Concrete is also commonly used but generally the steel roof frame would span the distance between tilt up pre-cast walls.

The image above is a recent development of a future Bunning’s warehouse on the gold coast. One of the great benefits of this construction is that a lot of the components are prefabricate and therefore commercially viable since they are quite repetitious.

Here you can see that most of the load is transferred from the steel rafters towards the columns. The structural beams have a shorter cross section and span longer distance. As most of the force is occurring in the join between beam and column this junction can be thickened to take and transfer the load.